A router is cheaper and easier to setup, but is limited by power and the rpms can not be controlled as precisely. Both options have pros and cons and I have not decided which to go with yet. This can, and will be remedied by either a cheap Chinese 1.5kw spindle. Moving the spindle fast strains the steppers and applies more force to the entire machine. One of the limitations is that the spindle does not have enough torque at lower rotation speeds, meaning you have to move it faster with a shallow depth of cut for optimal chip load. I opted to go with a 300w spindle, as it is the absolute cheapest one can buy. These motors are also a lot more expensive and require a larger psu adding more cost. Many who have built similar platforms have opted to use the larger nema 23's for their higher torque. There could be 2 underlying causes for this. This is only apparent while milling aluminum as can be seen below. This is when the force required to be issued by the stepper motor is more than it can handle and it "skips" a step.

Another issue holding the machine back is skipped steps. I did not use thread-locker on any screws which was a massive mistake that will be reprehended when I reassemble it into version 2. Issues and ChangesĪn issue you guys probably noticed in the earlier pictures are the screws all coming out due to vibrations of the machine. Here are some pictures of the controller box.

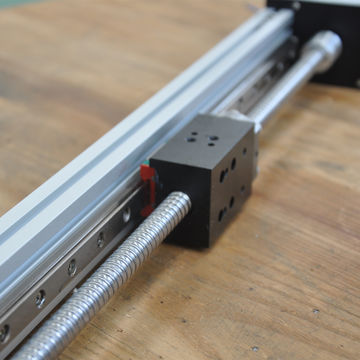

CNC LINEAR RAIL FULL

A full wiring guide will be released with the files. It is also extremely simple to wire up and get going with. This controller has a ton of features including + and - endstops for all 3 axis, toolpath simulation, pendent compatibility, and digital rpm control for spindles that support it. You simply put the GRBL Gcode files into a usb thumbdrive, plug it in, and hit start.

CNC LINEAR RAIL PC

While the price of this controller is more expensive than most at $160, it has full offline capability's meaning it does not have to be tethered to a pc in order to function. The main controller I have chosen to use for this build is the DDCSV2.1. A much more stiff table and enclosure have yet to come. Here are some pictures of the machine. For Right now the CNC is mounted to a poorly made temporary table. if you don't make sure that both motors are sychronised), can end up is similar or worse self locking problems.After a while with no updates, I finally have finished the first version of the project! While it still has many flaws that need to be sorted out before I can release files and instructions, it does in fact work. The dual motor design if not properly implemented (e.g. And that I'm afraid is something you can't read, you have to make mistakes and learn.Īnd just to be clear: what I said in the previous lines, does not mean that the power screw in the middle is worst that two power screws either way.

Generally, the most important thing is: not to overconstrain the assembly.

Generally they worked well, however the initial prototype was troublesome with respect to getting the alignment of the bars correct, and using linear bearings of proper tolerances (too tight tolerances, were not good when there were misalignments in the rods, while too loose were making the stage move like a drunk sailor in an alley). That was an experience I had when designing a (budget) linear translation stage (that was almost 10 years ago)ġ0 or so were build from these, (with different lengths - so only the rods had different lengths).

Surprisingly, even if the actuator is in the middle you might run into problems depending on the tolerance of the bearings. If you don't push it around the center of gravity you will cause it to rotate.Īlthough using linear bearings (especially longer ones) will mitigate the problem, you will be creating more normal forces, therefore more friction, and the motor will draw more Amps in order to provide the required torque. Imagine you have a pencil on a flat surface and you try to push. What happens in the arrangement is that you are applying a force away from the center of gravity.

0 kommentar(er)

0 kommentar(er)